3D Scanning for Quality Control

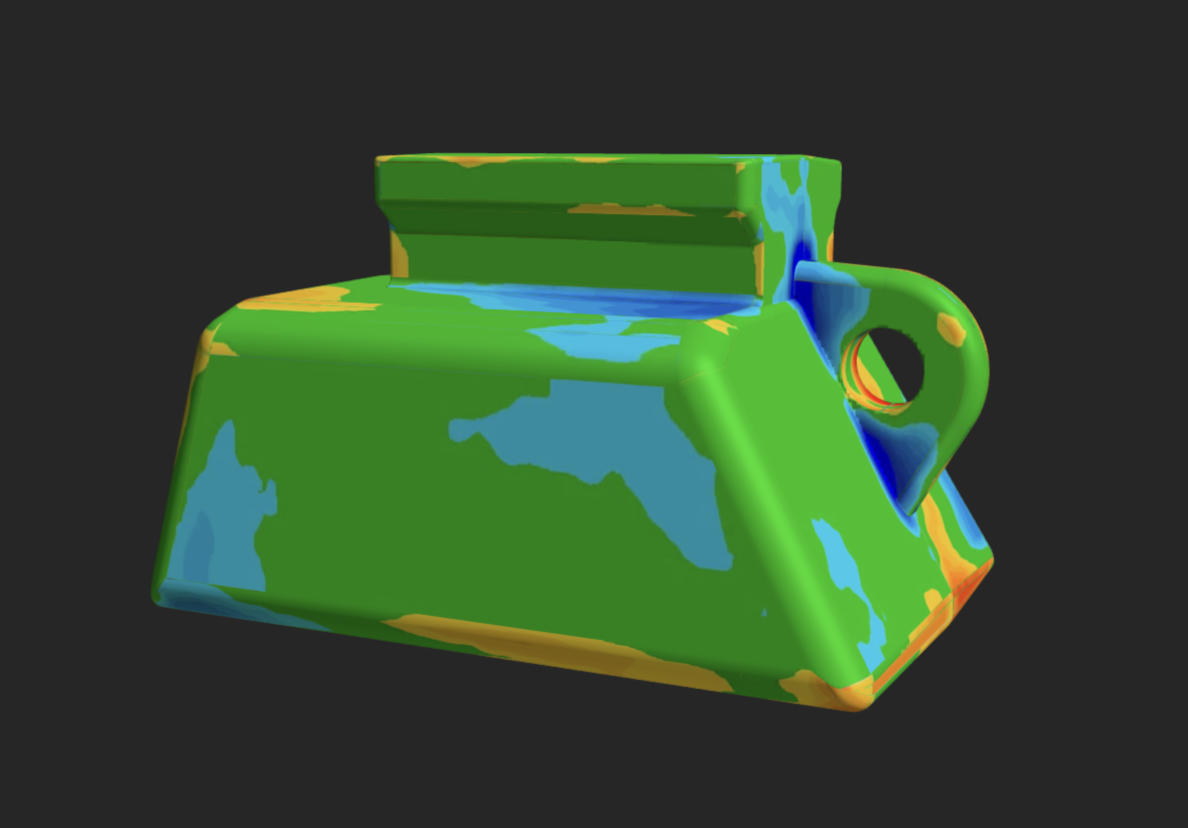

Deviation Map Comparing 3D Scan to CAD

Functional 3D is a 3D Scanning Service Provider used by manufacturers across a wide range of quality control applications. 3D Scanning for Quality Control allows manufacturers to 3D Scan to Check Deviation between digital designs and manufactured products. Quality Control is an integral part of manufacturing, and it's essential to ensure that the products meet all the necessary standards. 3D scanning offers several advantages over traditional inspection methods, including Enhanced Accuracy and Time Efficiency. Functional 3D offers quality control scanning services such as GD&T, Metrology 3D Scans, Quality Reports, and Deviation Maps From 3D Scans.

Contact us today to schedule a call

Applications of 3D Scanning for Quality Control

3D Scanning for GD&T, Metrology

3D Scanning for Quality Reports

3D Scanning for Deviation Maps

Functional 3D Structured Light and Photogrammetry Scanning Services can be used in a range of applications in the field of Quality Control. We take the time to meet with our clients before scanning in order to tailor our deliverables to meet the needs of every use case.

3D Scanning for Quality Control allows manufacturers to Digitize and Compare Manufactured Parts to CAD Designs.

Deviation Map from 3D Scan Data

Additionally, 3D Scanning for Quality Control allows manufacturers to collaborate remotely on part analysis, eliminating the need for trips to the manufacturing facility.

Functional 3D's Quality Control 3D Scanning Services are available to manufacturers across any industry.

Advantages of 3D Scanning for Quality Control

Enhancing precision and accuracy, 3D scanning streamlines quality assessment, integrating seamlessly into existing processes. This technology identifies discrepancies, providing detailed deviation maps for in-depth analysis, saving time and resources in the entire process.

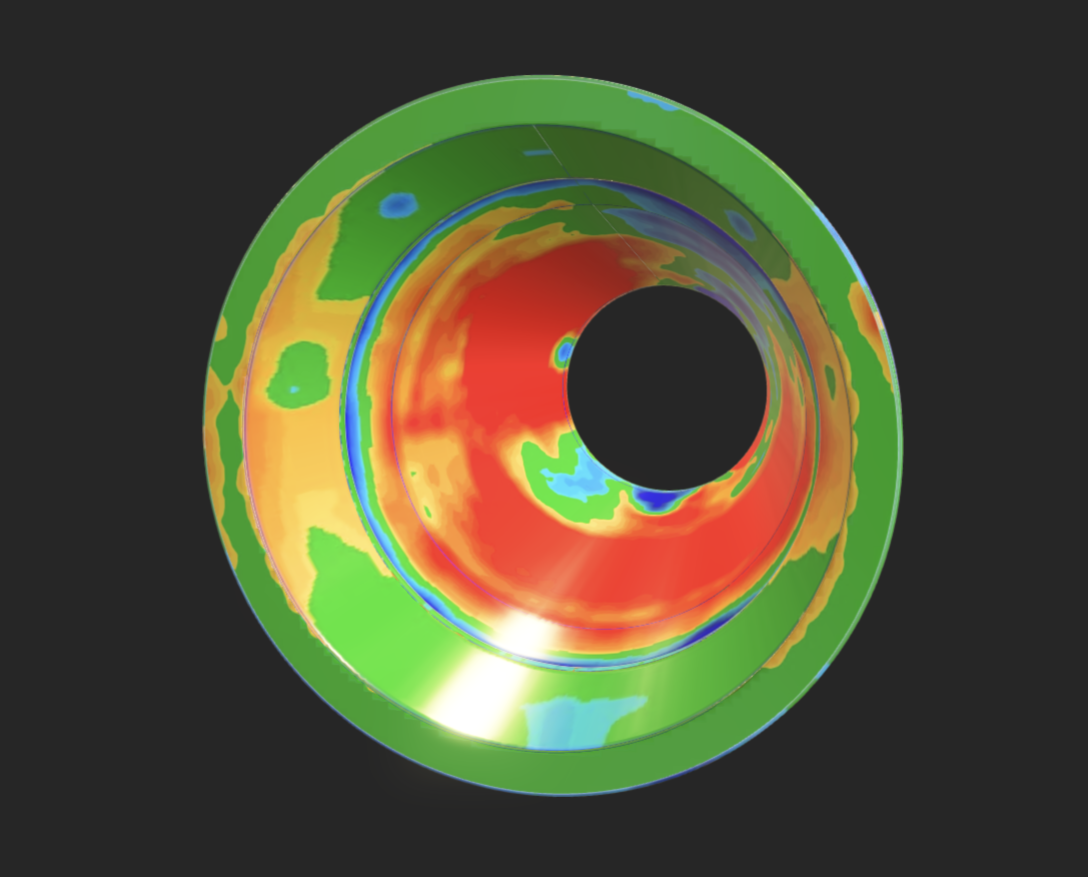

Complex Curvature Captured in Scan Data

Improving Efficiency of Quality Control with 3D Scanning

By enabling non-destructive testing and offering precise measurements, 3D scanning optimizes quality control. It detects defects early, saving time and resources in production. This technology is adaptable to varying production demands, making it cost-efficient for manufacturers.

3D Scan Data Being Used to Design Custom Fitted Part

Enhancing Accuracy in Quality Control with 3D Scanning

With 3D scanning services, quality control inspections benefit from unparalleled precision. This technology delivers exact data points for thorough quality analysis, ensuring strict quality assurance across the production line. Geometric dimensioning and surface finish assessment are significantly improved through quality control scanning, effectively inspecting product designs and specifications.

Seamless Integration into Existing Quality Control Processes

Seamless integration into existing production processes is a key advantage of 3D scanning. By quickly identifying defects and deviations, the technology streamlines quality control without disrupting workflow. The high level of accuracy prevents errors, reduces waste, and provides detailed data for analysis and decision-making, ultimately improving overall product quality and customer satisfaction.

Functional 3D’s Quality Control 3D Scanning Services offer precise measurements and defect identification for manufacturers. Our expertise and specialized equipment improves efficiency and accuracy of quality control, resulting in a reduction of costs. F3D takes the time to tailor all deliverables to meet each client’s specific needs.